All air conditioning systems and heat pumps depend on the refrigerants pressure temperature relationship. Like all liquefied gases, when refrigerant boils or evaporates, it absorbs heat at a very high rate. The refrigerant can be easily manipulated, since it has a lower boiling point than most liquids, so air at room temperature is the only heat source needed. The boiling point can be controlled is the pressure placed upon the liquid is altered.

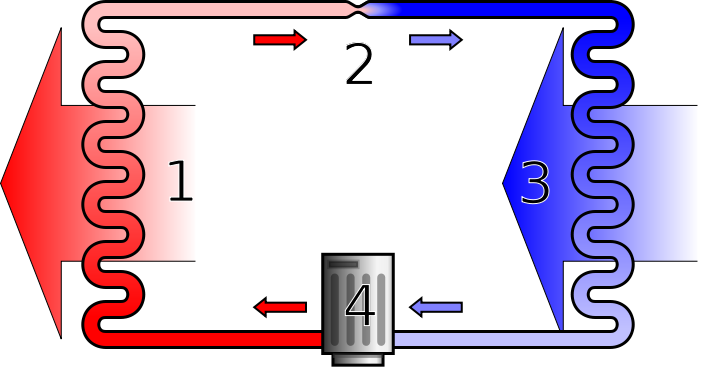

During the summer, the compressor, which is the heart of the heat pump, receives cool, low-pressure refrigerant vapor. This vapor is pumped to the side of the system that is under high pressure. The hot, high pressure gas then travels to the outside coil, which now functions as the condenser, through the reversing valve.

During the summer, the compressor, which is the heart of the heat pump, receives cool, low-pressure refrigerant vapor. This vapor is pumped to the side of the system that is under high pressure. The hot, high pressure gas then travels to the outside coil, which now functions as the condenser, through the reversing valve.

While in the condenser, heat is removed from the refrigerant by the outdoor fan so that it can be condensed into a liquid. By means of a one direction check valve, the liquid refrigerant can bypass the first expansion valve. The refrigerant, which is now cool and under high pressure, travels along the liquid line to the indoor unit and then forced through the second expansion valve. The flow of refrigerant becomes partially restricted, causing a decrease in pressure which is needed for the refrigerant to evaporate.

As it evaporates from the passing air, the refrigerant absorbs heat. Moisture is collected by the cold evaporator which provides dehumidification for the home. Then the refrigerant travels back to the compressor in order to repeat the process over and over again.